Use Cases

-

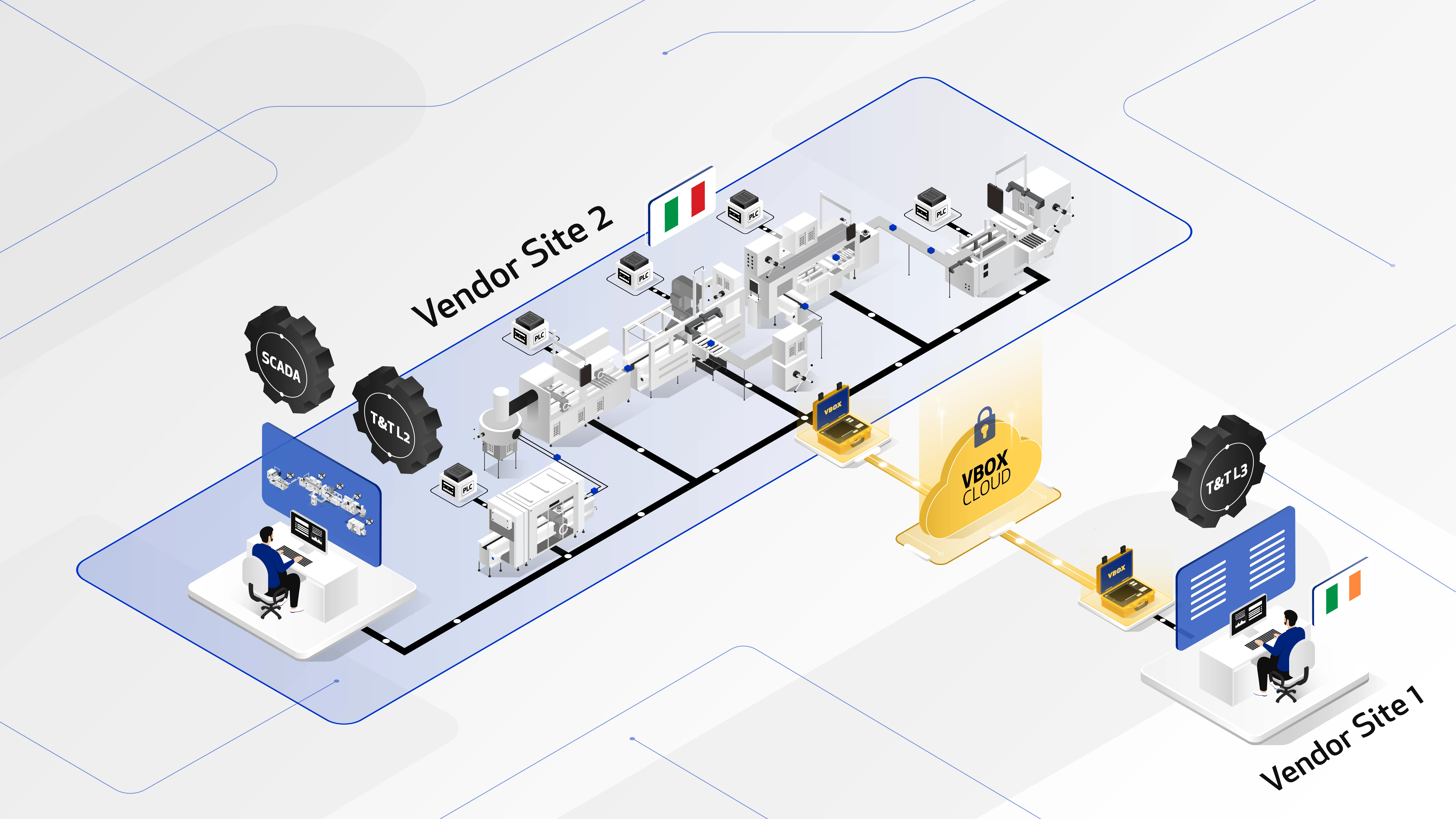

Track & Trace (T&T) L3 to L2 Integration testing at Vendor locationUsing VBOX enabled a T&T L3 system in Ireland (Vendor Site 1) to fully integrate seamlessly to a L2 Bio packaging Line located in the Italian Vendor FAT location (Vendor Site 2), which was connected to a second VBOX. Full L4 ⇒ L3 ⇒ L2 Integration was completed remotely over the secure VBOX connection.

Benefits:

The implementation of the VBOX solution enabled the seamless integration of the SAT Line with the Customer L3 Track & Trace (T&T) System in Ireland during the Factory Acceptance Testing (FAT) phase of the project. The availability of the complete Customer Serial Number lifecycle at the FAT stage ensured Plug & Play integration with the Customer Qualification T&T System, thereby enhancing project visibility and instilling confidence in the end customer regarding the successful deployment of a fully functional system upon delivery to the customer site.The following T&T tests were completed remotely using the VBOX Solution:

- Track & Trace - Seamless Customer L3 ⇔ L2 Process Order and Serial Number provisioning (Vendor Site 1 ⇔ Vendor Site 2).

- Track & Trace* - Seamless L2 ⇔ L3 Pallet-by-Pallet Aggregation data and Serial Number transfer during batch (Vendor Site 2 ⇔ Vendor Site 1).

- Track & Trace - Seamless L2 ⇔ L3 Batch End Aggregation data and unused Serial Number data transfer (Vendor Site 2 ⇔ Vendor Site 1).

Outcome:

- Accelerated Time-to-production: 8 weeks

- Consultancy costs avoided by Customer: 8 weeks

- Vendor was more efficient in project delivery.

- Customer & vendors allocated resources earlier to additional projects.

-

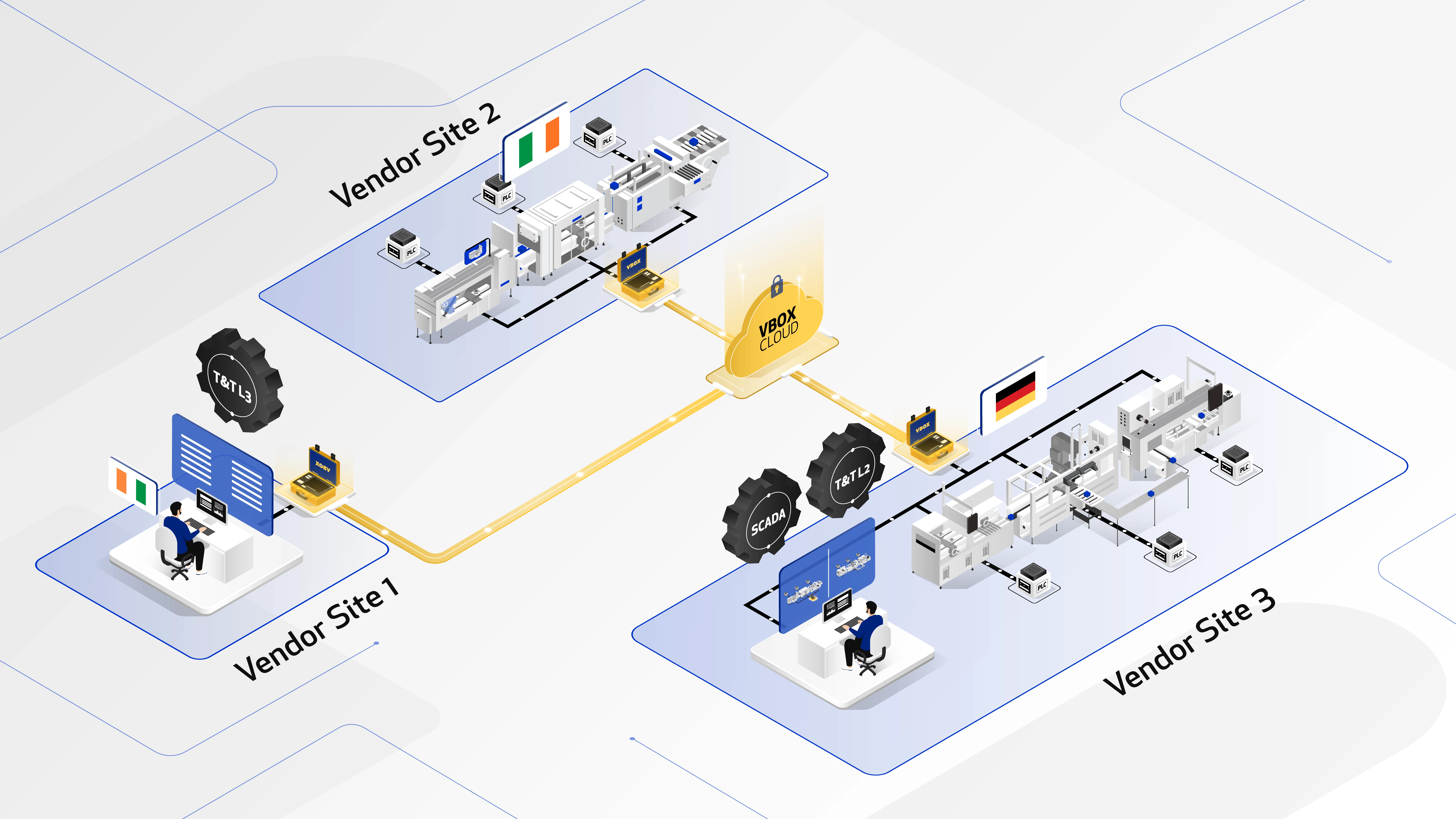

Full T&T/SCADA Line Integration Germany ⇔ Ireland at FAT LocationsVBOX enabled Full Remote Track & Trace (T&T) L3 Integration (Vendor Site 1) with the Start of Line installed in Ireland (Vendor Site 2), and the End of Line installed in Germany (Vendor Site 3) to occur earlier in the project.

Benefits:

The following tests were executed remotely using the VBOX Solution:

- SCADA - Network Integration allowing Batch Start to all machines in Real-Time (Vendor Site 2 & 3).

- SCADA - Audit Trail recording from all machines to Centralised SCADA system Database in Germany (Vendor Site 2 & 3).

- Track & Trace - Seamless Customer L3 ⇔ L2 Process Order and Serial Number provisioning (Vendor Site 1 ⇔ Vendor Site 3).

- Track & Trace* - Seamless L2 ⇔ L3 Pallet-by-Pallet Aggregation data and Serial Number transfer during batch (Vendor Site 3 ⇔ Vendor Site 1).

- Track & Trace - Seamless L2 ⇔ L3 Batch End Aggregation data and unused Serial Number data transfer (Vendor Site 3 ⇔ Vendor Site 1).

*These remote tests revealed serialisation issues with Pallet-by-Pallet upload during a batch, this required a fix by the vendor, a re-execution of the T&T System FAT, which led to the acceptance of the system by the customer.

The customer was extremely satisfied that all integration issues were identified and resolved at the Vendor FAT location prior to system delivery.

Outcome:

- Accelerated Time-to-production: 7.5 weeks

- Consultancy costs avoided by Customer: 7.5 weeks

- Vendor was more efficient in project delivery.

- Customer & vendors allocated resources earlier to additional projects.

-

MES EBR connectivity to Formulation machines at FAT stageUsing the VBOX solution, it became possible to execute MES EBR functions at the Irish Customer Site, such as valve activation, vibration activation, and blending initiation. These functions were received in real-time at the FAT location in Germany (Vendor Site), allowing SAT integration tests to be performed earlier in the project.

Benefits:

The incorporation of the complete Customer Electronic Batch Record (EBR) process during the Factory Acceptance Testing (FAT) phase facilitated a smooth integration with the Customer Formulation Process at the subsequent Customer Site Acceptance Testing (SAT) phase. This integration significantly enhanced project visibility, instilling confidence in the successful deployment of a fully operational system at the Customer Site.

No issues were present for the SAT or Operational Qualification.

Outcome:

- Accelerated Time-to-production: 4 weeks

- Consultancy costs avoided by Customer: 4 weeks

- Vendor was more efficient in project delivery.

- Customer & vendor allocated resources earlier to additional projects.

-

Point-to-Point Private VPNVBOX enabled a critical validated machine (e.g. SEPHA VisionScan - Pin hole integrity tester) to be sent to the FAT location of an Italian Flow wrapper machine (Vendor Site). In doing so, VBOX allowed remote access to the SEPHA machine to assess the performance of the flow wrapper machine during FAT - without having an Internet connection (thus preventing unwanted automatic software updates etc.). VBOX removed the need for a production resource to travel to the FAT location as the SEPHA machine was remotely accessible from the Customer Site, thus optimising resources.

Benefits:

Facilitated Remote Witnessing of Vendor FAT Tests: Our solution empowers vendors to conduct Factory Acceptance Tests (FAT) while allowing remote witnessing, eliminating the necessity of deploying customer resources to the FAT location.

Established Secure Remote Connectivity to Critical GMP Systems: VBOX successfully established secure remote connectivity to critical Good Manufacturing Practice (GMP) systems via the Internet, ensuring that these systems remain isolated from the Internet while maintaining operational integrity.

No issues were present for the SAT or Operational Qualification.

Outcome:

- Accelerated Time-to-production: 3 weeks

- Consultancy costs avoided by Customer: 3 weeks

- Vendor was more efficient in project delivery.

- Customer & vendor allocated resources earlier to additional projects.